Characteristics of acrylic plate:

1. Relatively high light transmittance: plexiglass is the most excellent transparent raw material of polymer material, with a light transmittance of 92%, which is higher than laminated glass. 2. High impact toughness: The relative molecular weight of polymethyl methacrylate is about 2 million, which is a long chain macromolecular material chemical, and the chain that generates the molecular structure is very soft. Therefore, the hardness of polymethyl methacrylate is very high, and its tensile and impact resistance is 7-18 times higher than that of ordinary glass. 3. Light weight: the relative density of plexiglass is 1.18kg/dm3, and the net weight of raw materials of the same size is only half of that of ordinary glass and 43% of that of metallic aluminum (belonging to non-metallic materials). 4. It is convenient for production and processing: plexiglass can not only be drilled with a CNC lathe and drilled with a planer, but also be bonded into various shapes with toluene, ether and other materials, as well as injection molding and injection Extrusion and other plastic forming methods are used to produce and process airport seat covers, ranging from removable dentures and dental brackets. Acrylic plate has the following advantages: Visual function: colorful, colorful, strong visual impact; Weather resistance: it can be stored for a long time without fading, and the quality of the board can reach 8 - 15 years; Durability: This product has an outstanding maintenance effect on the built-in light source and extends the service life of the light source product. Rationality: reasonable planning, rainproof and moisture-proof, open structure, convenient maintenance; Impact resistance: 2GG times of glass products, virtually no risk of fracture; Light transmittance: the light transmittance is up to 95%, with good light transmittance and soft light; Flame retardant: non self igniting and self extinguishing; Acrylic logo Beautiful: beautiful workmanship, good mirror effect, no wrinkles, seamless, all riveted fasteners are not exposed; Energy saving: good light transmittance, reduce light source, electricity and use cost. Application of acrylic plate: 1. Construction purposes: shop windows, sound insulation doors and windows, lighting masks, telephone booths, etc. 2. Advertising application: light box, signboard, sign, display frame, etc. 3. Transportation application: doors and windows of trains, automobiles, etc. 4. Medical use: baby care box, various surgical medical instruments, civil products: sanitary facilities, handicrafts, cosmetics, brackets, aquariums, etc. 5. Industrial use: appearance, panel, cover, etc. 6. Lighting application: fluorescent lamp, pendant lamp, street lamp cover, etc. 7. Household: fruit tray, tissue box, acrylic art painting and other household products

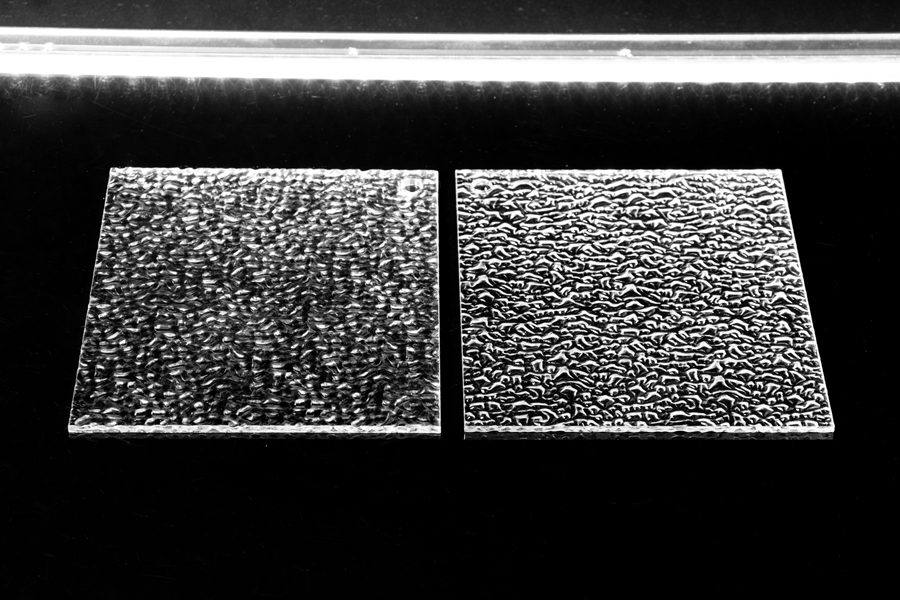

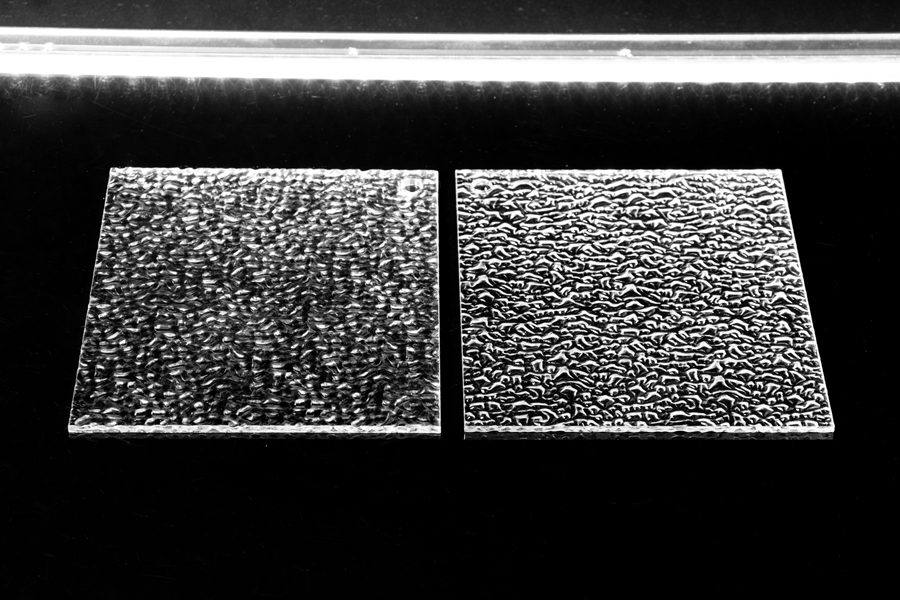

Jiangmen Kunxin New Material Technology Co., Ltd has got over 10 years in Polycarbonate sheets and Acrylic Sheets manufacturing and supplying, and achieve two brand "J.K Optics" and "KunXin plas", which specialize in the optical Acrylic and Polycarbonate diffusion sheet and Textured Acrylic Panel manufacturing separately , has been serving the lighting industry & decoration material market for more than 10 years, products included: Light Diffuser.Optical Diffuser Film & Reflector.Light Guide Plate.Clear Acrylic Sheet.Reeded Or Stripe Acrylic Sheet.Textruded Acrylic Sheet;