Acrylic, also known as plexiglass with special treatment, is a replacement product of plexiglass. The light box made of acrylic has good light transmission performance, pure color, rich color, beautiful and smooth, taking into account both effects of day and night, long service life, and does not affect the use, etc. Features. In addition, Acrylic Sheet and aluminum composite panel profiles, advanced screen printing, etc. can be perfectly combined to meet the needs of businesses. Acrylic blister is the best form of outdoor advertising to improve the level of business stores and unify corporate image.

It can be divided into acrylic casting board, acrylic extruded board and acrylic board material classification. Acrylic Cast Sheet: High molecular weight, excellent stiffness, strength, and excellent chemical resistance. This board is characterized by small batch processing, unparalleled flexibility in color system and surface texture effect, and complete product specifications for various special purposes. Acrylic extruded sheet: Compared with cast sheet, extruded sheet has lower molecular weight and slightly weaker mechanical properties. However, this feature facilitates bending and thermoforming, and when dealing with larger size sheets, it facilitates rapid vacuum forming. At the same time, the thickness tolerance of the extruded sheet is smaller than that of the cast sheet. Due to the large-scale automatic production of extruded boards, it is inconvenient to adjust the color and specifications, so the variety of product specifications is limited to a certain extent. The material classification of acrylic board is mainly divided into three categories in China: one is imported board; the other is Taiwan-funded board; the third is domestic board. They differ in the origin and (MMA) purity of the raw materials used. This is also the key to determining the quality and price of the board. Features of acrylic sheet: Good weather resistance and acid and alkali resistance, no yellowing and hydrolysis caused by years of sun and rain; long life, more than three years longer than other materials; good light transmittance, up to 92 % or more, the required light intensity is small, saving electric energy; strong impact resistance, sixteen times that of ordinary glass, suitable for installation in areas that require special safety; excellent insulation performance, suitable for various electrical equipment; light weight, compared to Ordinary glass is half lighter, and the load on buildings and brackets is small; bright colors and high brightness are unmatched by other materials; strong plasticity, large changes in shape, easy processing and forming; high recyclability, which is driven by the growing awareness of environmental protection Agreed; easy to maintain, easy to clean, rainwater can clean naturally, or scrub with soap and a soft cloth. The advantages of acrylic sheet: 1. Excellent transparency acrylic sheet, colorless and transparent plexiglass sheet, light transmittance of more than 92% 2. Excellent weather resistance, strong adaptability to the natural environment, even if it is exposed to sunlight, wind and rain for a long time, its performance will not change. It has good anti-aging performance and can be used outdoors with peace of mind. 3. Good processing performance, suitable for both machining and thermoforming 4. Excellent comprehensive performance, acrylic sheet has a wide variety, rich colors, and has extremely excellent comprehensive performance, providing designers with a variety of choices. The acrylic sheet can be dyed, and the surface can be painted, silk screened or vacuum coated. 5. Non-toxic, even if it is in contact with people for a long time, it is harmless, but formaldehyde and carbon monoxide will be produced when the combustion is incomplete. 6. The linear expansion coefficient of the cast plate is about 7x10-5m/m.K. Acrylic sheet use: 1. Architectural applications: shop windows, soundproof doors and windows, lighting covers, telephone booths, etc. 2. Advertising applications: light boxes, signs, signs, display stands, etc. 3. Transportation applications: doors and windows of trains, cars and other vehicles, etc. 4. Medical applications: baby incubators, various surgical medical instruments, civilian products: sanitary facilities, handicrafts, cosmetics, brackets, aquariums, etc. 5. Industrial application: instrument panel and cover, etc. 6. Lighting applications: fluorescent lamps, chandeliers, street lampshades, etc.

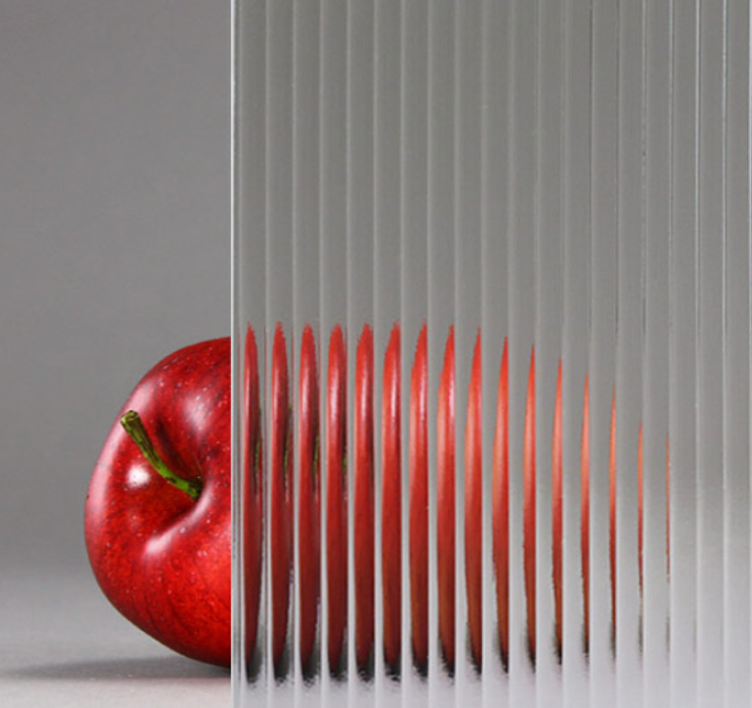

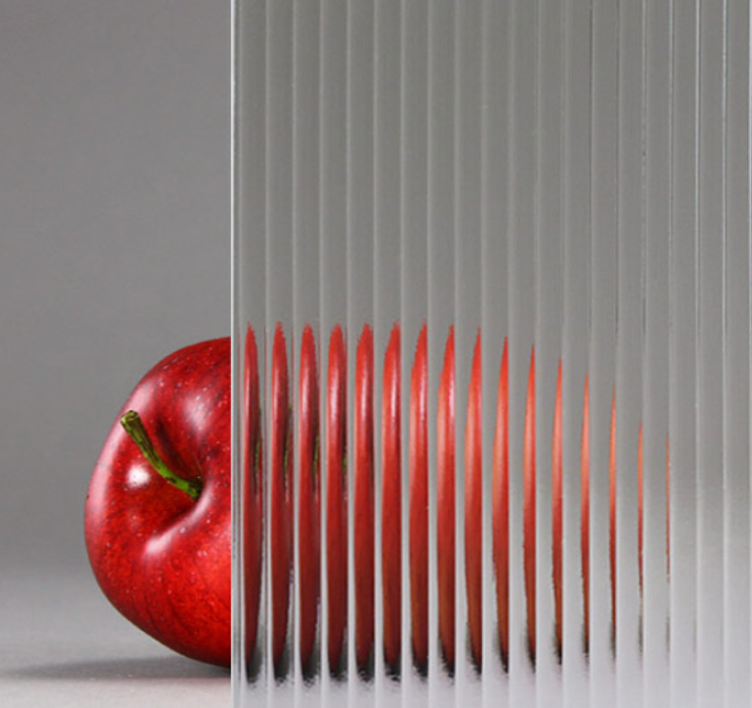

Jiangmen Kunxin New Material Technology Co., Ltd has got over 10 years in Polycarbonate sheets and Acrylic Sheets manufacturing and supplying, and achieve two brand "J.K Optics" and "KunXin plas", which specialize in the optical Acrylic and Polycarbonate diffusion sheet and Textured Acrylic Panel manufacturing separately , has been serving the lighting industry & decoration material market for more than 10 years, products included: Light Diffuser.Optical Diffuser Film & Reflector.Light Guide Plate.Clear Acrylic Sheet.Reeded Or Stripe Acrylic Sheet.Textruded Acrylic Sheet;