Forming process of acrylic sheet

2022-07-30

Acrylic molding processes commonly used in industrial production include casting, injection molding, extrusion, thermoforming, etc.

Casting molding is mainly used for the molding of acrylic sheets, bars and other profiles, and the molded products need to be post-processed before they can be used. Cast Acrylic Sheet has strong stiffness, strength and excellent chemical resistance, and has unparalleled flexibility in color system and surface texture effect.Extrusion molding is to extrude the acrylic particles produced by suspension polymerization into acrylic sheets, rods, pipes, sheets, etc. Acrylic products made by extrusion molding have low molecular weight, weak mechanical properties, low heat resistance and solvent resistance, but this process has high production efficiency and high product flexibility, which is conducive to bending and thermoforming.

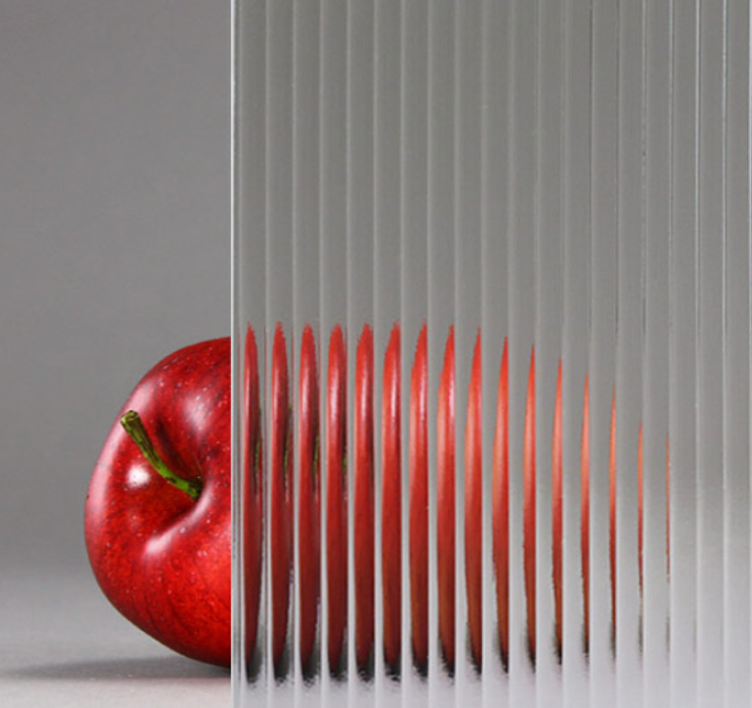

Jiangmen Kunxin New Material Technology Co., Ltd has got over 10 years in Polycarbonate sheets and Acrylic Sheets manufacturing and supplying, and achieve two brand "J.K Optics" and "KunXin plas", which specialize in the optical Acrylic and Polycarbonate diffusion sheet and Textured Acrylic Panel manufacturing separately , has been serving the lighting industry & decoration material market for more than 10 years, products included: Light Diffuser.Optical Diffuser Film & Reflector.Light Guide Plate.Clear Acrylic Sheet.Reeded Or Stripe Acrylic Sheet.Textruded Acrylic Sheet;